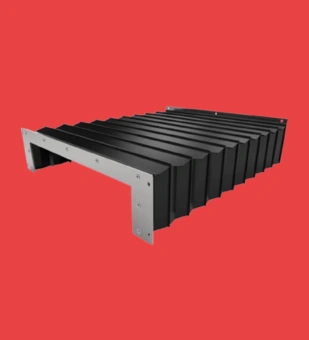

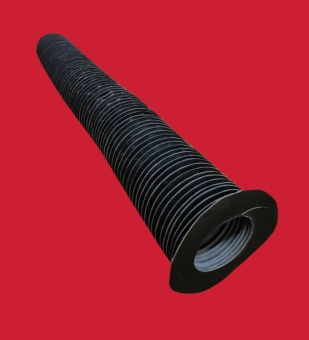

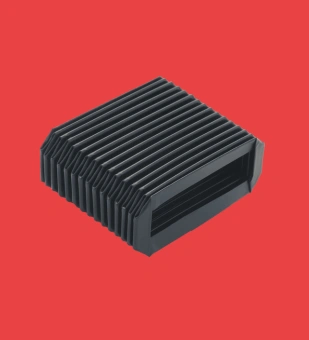

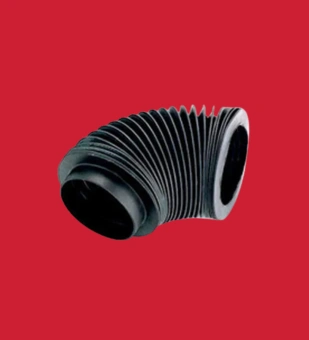

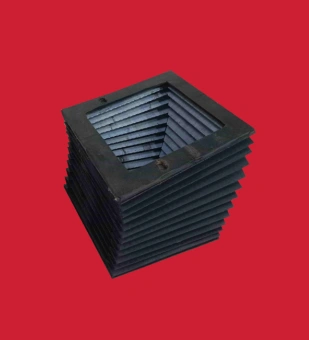

Round Bellow Cover

Leak Prevention

Efficient Sealing

Vibration Control

Durable Performance

Temperature Resistance

- Home

- Round Bellow Cover

How to Choose the Right Round Bellow Cover Manufacturer?

The quality round bellow cover manufacturer delivers products that extend equipment life. These special covers prevent dust, oil, and water from damaging critical components. Manufacturing precision directly affects their performance. The bellow covers maintain flexibility while resisting tears and chemical damage. They fit perfectly around moving parts without stopping the necessary movement.

The material quality is responsible for resistance to cuts, abrasions and chemical exposure. These covers reduce maintenance costs and prevent unexpected equipment failures.

Ready to See your Idea into Reality

We have served 157+ Clients so far…Discuss your Requirements with Our Experts.

Round Bellow Cover In Industry

Our Products

Steps To Choose the Right Round Bellow Cover Manufacturer

1. Assess Manufacturing Capabilities

A reliable round bellow cover manufacturer uses advanced CNC machining to deliver precision parts that fit perfectly every time.

The machinery should create consistent products with minimal variance between batches. Their custom sizing options are necessary as the standard dimensions won't work for specific applications. The volumes of the production capacity affect the delivery schedules of large orders.

A facility equipped to handle varying quantities prevents delays during busy seasons. The quality control systems must include multiple checkpoints throughout the manufacturing process. They should be able to do regular inspections and catch potential issues before products leave the facility.

The in-house testing facilities demonstrate a commitment to product reliability and performance standards. These testing areas should simulate real-world conditions where bellows operate.

The material handling expertise affects both product quality and production efficiency. They should be able to handle properly to prevent contamination and ensure material integrity throughout production.

2. Evaluate Material Quality

The material selection impacts performance in demanding industrial environments. A competent custom round bellow cover supplier would provide different silicone durability measurements on diverse applications.

The most appropriate suppliers present data sheets that discuss performance specifications. The covers have rubber compound choices that ought to suit detailed environmental conditions in which they will be used.

The range of temperature resistance is important in cases where bellows are exposed to extreme temperatures (either hot or cold). The proper materials should be flexible and structurally sound to work within the range of operational temperatures.

The intoxication tolerance to the chemical defines all-time survival in the oil, solvent or acid environment. This resistance prevents premature breakdown when covering contact industrial chemicals.

The UV resistance properties become crucial for outdoor applications with sun exposure. The strong UV protection prevents cracking and colour degradation over long periods.

| Common Round Bellow Cover Materials | ||||

| Material Type | Temperature Range | Chemical Resistance | Flexibility | Applications |

| Silicone | -60°C to 230°C | Moderate to High | Excellent | Medical, Food Processing |

| EPDM Rubber | -40°C to 150°C | Good | Very Good | Outdoor Equipment |

| Neoprene | -20°C to 100°C | Good | Good | General Industrial |

| Nitrile | -30°C to 120°C | Excellent | Moderate | Oil and Gas Equipment |

| Viton | -15°C to 200°C | Excellent | Moderate | Chemical Processing |

Countries

Industries Served

Projects

Clients

3. Review Industry Experience

An established industrial round bellow cover maker brings valuable knowledge to complex projects. Their years in operation provide insight into common application challenges. This helps anticipate potential issues before they arise. The industry specialisations reveal expertise with specific sectors like automotive or food processing.

The manufacturers understand the unique requirements for different industrial applications. Their client retention rates offer clues about reliability and customer satisfaction levels. You should ask about their long-term relationships. This will suggest consistent quality and responsive service.

You ask for their project portfolio diversity. It will demonstrate flexibility to all kinds of technical challenges and requirements. The presence of diverse projects is also indicative of being versatile when it comes to managing various specifications and industries.

Many manufacturers should explain material options and design considerations. They should have a proper track record. It will demonstrate the level of company efficiency in terms of how they raise issues that emerge without prior notice.

4. Verify Certification Standards

The manufacturers producing flexible round rubber bellow cover products should maintain proper documentation. ISO 9001 certification confirms adherence to internationally recognised quality standards. This ensures consistent manufacturing processes across all production runs.

Material safety certifications protect workers and end-users from harmful substances. These documents verify compliance with health and safety regulations. It is necessary for them to have proper waste management and emissions control.

The standards peculiar to industry respond to specific needs in such special areas as medical equipment. Such special certifications confirm the appropriateness of handling critical applications.

5. Check Production Flexibility

The manufacturers offering high durability round bellow protective covers consider quality and adaptability in one. Their customisation capability enables them to make alterations to common designs. The skill sets are used to handle special application problems.

The prototype development service also allows an opportunity to test the results prior to full production. The prototypes assist in detecting possible design enhancements prior to actual production. Small batch options are available to meet the small requirements of quantity in projects or to meet the requirements of testing.

The mass production power provides stability in the supply chain for continuous or massive demand. They are to be scalable so that they may keep quality despite the size of the order.

The manufacturing companies ought to be in a position to take up immediate projects with the intention of meeting emergency replacement or emergency projects. The change processes of the design must be efficient to deal with changes and without delays.

6. Examine Customer Support

The manufacturers should be able to provide reliable support. Their access shows their loyalty to product success with customers. The engineers would be available to provide answers to specifications or applications.

After-sales service quality demonstrates long-term commitment to customer satisfaction. The good service includes installation advice and troubleshooting assistance when needed. The warranty policies should clearly state coverage terms and claim procedures. Strong warranties indicate the manufacturer's confidence in their product quality.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.