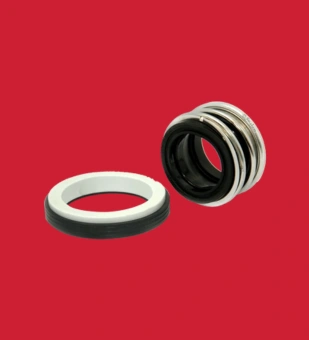

Rubber Bellow Seal

Long Lifespan

Noise Reduction

Consistent Quality

Low Maintenance

Reliable Performance

- Home

- Silicone Rubber Bellow Seals

How Silicone Bellow Seals Perform in Extreme Heat and Chemical Exposure?

The reliable performance of silicone rubber bellow seals makes them essential components. These special seals serve critical functions in pumps across various industries. They maintain flexibility while blocking leaks in challenging mechanical junctions. The unique accordion-like design allows for movement.

The engineers must consider temperature ranges when selecting appropriate sealing materials. The right seal choice significantly reduces maintenance costs and system downtime. Manufacturing facilities cannot afford leaks in their critical process equipment.

Ready to See your Idea into Reality

We have served 157+ Clients so far…Discuss your Requirements with Our Experts.

Silicone Rubber Bellow Seals In Industry

Our Products

Heat Performance of Silicone Bellow Seals

The silicone bellow seals maintain their elasticity across shocking temperature ranges. Most industrial applications demand materials that won't fail when things heat up.

The flexible silicone bellow seals offer resilience where other materials quickly degrade. Many engineers choose these seals for their consistent performance in thermal cycling situations. The unique molecular structure gives silicon its heat tolerance properties.

1. Temperature Capabilities

The operational range starts from frigid -60°C all the way to 230°C. Their regular exposure to this range won't degrade the material's core properties. The short-term spikes up to 300°C can be tolerated without permanent damage.

The cold environments don't cause the brittleness seen in conventional rubber products. The material stays pliable even when temperatures plummet below freezing points.

2. Heat Degradation Indicators

Watching for specific signs helps predict seal failure before leaks occur. Any surface cracking appears as the first warning of heat stress. The compression set becomes evident when seals no longer bounce back properly.

The edges might show signs of brittleness or material flaking. Any gaps begin forming as the material structure changes under heat stress. Their regular inspection prevents catastrophic failures in critical industrial applications.

Chemical Resistance of Silicone Bellow Seals

The high temperature silicone rubber seals resist many common industrial chemicals. Their molecular structure repels certain substances while remaining vulnerable to others.

The resistance profile must match precisely with the application environments. The manufacturers should understand these limitations before installation in chemical systems. The testing under actual conditions is the best standard for validation.

The water exposure poses no threat to these versatile sealing components. Steam environments actually highlight the material's excellent performance characteristics. The dilute acids and bases interact minimally with the polymer structure.

Most alcohols and certain ketones won't deteriorate the material integrity. The seals maintain stability during prolonged exposure to UV and ozone.

The petroleum-based fuels quickly attack and degrade silicone's molecular bonds. Many industrial oils cause swelling that compromises sealing effectiveness. The industrial silicone rubber bellow seal products fail when exposed to concentrated acids.

The chlorinated solvents represent another category that rapidly damages these seals. The compatibility limitations should be evaluated during engineering design phases.

| Silicone Bellow Seal Chemical Compatibility Chart | |||

| Chemical / Media | Compatibility | Effect on Seal | Max Safe Exposure |

| Water (Hot/Cold) | Excellent | None | Continuous |

| Steam (up to 150°C) | Good | Minor hardening | Long-term |

| Ethanol | Good | Slight swell | Moderate |

| Acetone | Limited | Swelling | Short-term only |

| Dilute HCl (10%) | Good | Minimal | Moderate |

| Sodium Hydroxide | Good | Minimal | Long-term |

| Gasoline | Poor | Severe swell | Avoid |

| Diesel Fuel | Poor | Breaks down | Avoid |

| Mineral Oil | Poor | Softens seal | Avoid |

| Sulfuric Acid (Conc.) | Poor | Corrodes fast | Avoid |

| Ozone | Excellent | None | Continuous |

| UV Light | Excellent | None | Continuous |

Countries

Industries Served

Projects

Clients

Best Use Cases for Silicone Bellow Seals

The food processing industry relies on these special components. Food grade silicone bellow seals prevent contamination in sensitive production environments. These materials meet strict regulatory requirements for consumable manufacturing facilities. The non-toxic composition ensures safety in applications touching edible products.

Many pharmaceutical equipment include these seals throughout mixing and reaction vessels. They are preferred over other temperature-resistant sterilisation methods. The inexpensive outgassing properties of silicon are advantageous to clean room environments. The substance does not allow impurities into highly regulated drug production.

The HVAC systems undergo variations in temperatures during working periods. The seals are able to sustain thousands of thermal cycles. Their flexibility prevents air leaks that would reduce system efficiency. The climate control systems depend on these components for reliable performance.

Medical, Water Treatment, and High-Temperature Pumping Applications

Silicone is used in the manufacturing of medical devices for critical sealing needs. The biocompatibility profile is of high standards required in the healthcare industry. The sterilising reactions do not affect the physical characteristics of the material.

The silicone rubber bellow seals are used in the process of a water treatment plant. The resistance of the material to chlorine makes it suitable for such conditions. The water exposure doesn't lead to degradation or contamination issues. Municipal water systems rely on these dependable sealing solutions.

Silicone helps in the special pumping systems to handle low-oil content fluids. The heat resistance prevents failures in high-temperature pumping applications. These components maintain their flexibility despite punishing operational conditions. The engineers specify silicon for the most demanding thermal environments.

When to Avoid Silicone Bellow Seals?

Some applications simply don't match well with silicone's material properties. Environments with constant fuel exposure quickly destroy these sealing solutions. The material swells, loses elasticity and ultimately fails to maintain seals. The alternative elastomers provide better performance in these specific situations.

Chemical processing facilities handling concentrated solvents need different solutions. The custom silicone bellow seal manufacturer recommends alternatives for these applications. The incompatibility of material with the chemical environments is an economic liability.

The sealing materials have to be stronger in the high-pressure systems transporting hydrocarbons. The silicone lacks the necessary tear resistance for these demanding applications. The pressure ratings fall short of what the petroleum industries require. The choice of the material must have application-specific performance considerations.

Ways To Choose Silicone Seals

These silicone bellow seals are the best choice for many situations. Understanding both strengths and limitations ensures appropriate application selection. The temperature and chemical resistance profiles are responsible for the selection of suitable operational environments.

- Prolonged contact with aromatic hydrocarbons causes irreversible material degradation

- Continuous mechanical abrasion quickly wears down the soft surface

- Pressure ratings max out lower than fluorocarbon alternatives

- Temperature fluctuations above 300°C lead to accelerated material breakdown

- Cost factors may outweigh benefits in non-critical, low-temperature applications

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.