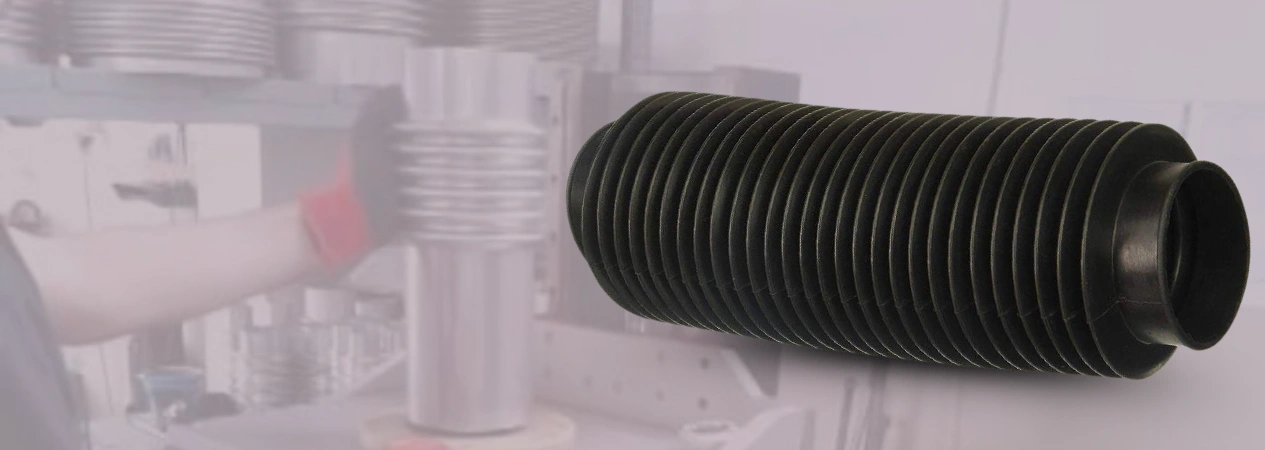

High Flexibility Bellows

High Durability

Shock Absorption

Heat Resistance

Enhanced Insulation

Reliable Performance

- Home

- High Flexibility Bellows

Why High Flexibility Bellows Are Critical in Modern Industrial Machinery?

The machines operate under extreme conditions that rigid connections simply cannot handle. The special design allows for movement while maintaining critical seals against leaks. The engineers rely on these components to solve complex motion problems.

The high flexibility rubber bellows prevent equipment damage by absorbing unwanted movement patterns. Their unique construction handles expansion, vibration, and misalignment. Many systems would quickly fail under normal operation without these flexible elements. The corrugated design creates movement capability that rigid pipes cannot match.

The right bellows selection extends equipment life and reliability. Most industrial facilities depend on these components for smooth operation.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

High Flexibility Bellows In Industry

Our Products

What Are High Flexibility Bellows?

Bellows are made up of corrugated tubes with a thin wall which can easily bend. The design can move in any direction without the seal breaking. The accordion-like features of them give it a spring effect that is self-forming after compression. Most systems rely on bellows when rigid parts would quickly fail under stress.

The manufacturing process creates precise corrugations that determine movement capabilities. The fold adds to the overall flexibility while maintaining structural integrity.

The materials vary based on application needs and environmental conditions. The thickness and pattern directly impact how much stress they can handle. Many production techniques allow for incredible precision in these critical components.

Functional Benefits and Application Advantages

The high flexibility rubber bellows offer a movement range compared to rigid connectors. This flexibility prevents catastrophic failures in systems with shifting components. The engineers define the bellows depending on the anticipated movement characteristics and the level of stress. The right selection extends equipment life and performance capacity.

- Allow for thermal expansion in hot processing environments

- Create barriers between incompatible substances

- Enable precise movement in automated systems

- Reduce maintenance frequency in moving assemblies

- Protect sensitive equipment from environmental factors

Functions in Industrial Machinery

The industrial equipment faces constant movement challenges that rigid components cannot handle. One way that bellows addresses this issue is by absorbing thermal expansion in hot systems.

The variations in temperature cause the metals to swell and contract during the operational cycles. This relocation poses serious strains on the connections that are not well compensated. The elasticity does not allow the pipe to burst and damage the equipment when running normally.

The other highly dangerous effect on machine functionality and life is vibration. Constant patterns are created by the rotating motors, pumps, etc. These vibrations travel through connected systems and cause premature wear.

The flexible expansion bellows dampen these vibrations before they damage sensitive components. The reduction in transmitted force protects both equipment and surrounding structures.

Misalignment Compensation and Environmental Protection

Misalignment happens even in right systems due to settling and wear. Connecting pipes rarely maintain alignment throughout their service life.

The industrial flexible rubber bellows compensate for these positioning errors without leaking. This capability reduces stress on flanges and other rigid connection points. Many systems would quickly fail without this crucial adjustment capability.

Dust, chemicals, and other contaminants damage moving components rapidly. The bellows create effective seals around shafts, rods, and actuating elements. This barrier prevents contamination while still allowing necessary movement. The systems extend equipment life in harsh operating environments.

| Industries That Rely on High Flexibility Bellows | ||

| Industry | Application | Why Flexibility Matters |

| Oil & Gas | Pipeline expansion joints | Extreme temp swings, ground shifts |

| Pharmaceutical | Sterile valve seals | Zero contamination, frequent cleaning |

| Semiconductor | Vacuum chamber seals | Ultra-pure environment, precise motion |

| Aerospace | Fuel system connectors | High vibration, weight limits |

| Food Processing | Hygienic pump seals | Wash-down cycles, FDA compliance |

| Automotive | Exhaust flex pipes | Engine vibration, heat cycling |

| Power Generation | Turbine duct connectors | Thermal growth, seismic movement |

Countries

Industries Served

Projects

Clients

Material Choices and Their Benefits

Many industrial applications demand materials that withstand specific operating conditions. The selection process must consider temperature, pressure, and chemical exposure. Different materials offer unique advantages for particular environments. The engineers must balance cost considerations against performance requirements.

1. Metal Bellows Options

Stainless steel bellows handle extreme temperatures exceeding 800°C without failure. These components maintain their elasticity even after thousands of cycles. The corrosion resistance protects against aggressive chemical environments. The custom high flexibility bellows made from metals offer precise performance specifications. The application may require specific alloy formulations for optimal results.

2. Rubber and Elastomer Solutions

The elastomeric materials provide exceptional movement range at lower cost points. The flexible rubber bellows manufacturer creates products for less demanding applications. These components excel at vibration damping in normal temperature ranges. Their flexibility exceeds metal alternatives when pressure requirements remain moderate.

3. Advanced Polymer Choices

PTFE and silicone high flexibility bellows deliver outstanding chemical resistance. These materials remain inert when exposed to aggressive process fluids. The food processing and pharmaceutical applications require these special materials. The non-stick surface prevents product buildup during operation. The temperature stability ranges from cryogenic to moderately high heat applications.

Signs You Need Higher Flexibility Bellows

System performance often declines gradually as bellows approach failure points. The cracks appearing in existing bellows indicate material fatigue. These warning signs should trigger immediate evaluation and replacement planning. Any small cracks quickly expand into catastrophic failures during normal operation.

The leak detection represents another critical indicator of imminent bellows failure. Moisture, process fluids, or pressure loss signals compromise bellows integrity. The regular inspection should focus on connection points and bellows surfaces. Discolouration around joints often indicates microscopic leakage before visible drips. Any temperature changes around the bellows may also indicate developing leakage problems.

Any excessive vibration and noise levels signal inadequate flexibility in current components. The functioning bellows absorb movement without transmitting forces to connected equipment. Vibration increases indicate declining absorption capability from ageing materials.

Stress Indicators and System Changes of the Bellows

The sound meters can detect early changes before human perception notices. One needs to address these symptoms early to prevent damage to surrounding equipment.

Flange failures and pipe stress indicate insufficient movement accommodation in systems. The bellows should absorb motion rather than transferring stress elsewhere. Higher temperatures than the original design specifications require more flexible alternatives. Equipment upgrades often demand corresponding bellows improvements for proper function.

Frequent maintenance provides clear evidence of inadequate bellows performance. The components should last through planned maintenance cycles. Any premature replacement indicates either wrong specification or changing conditions. Analysis of failure patterns helps identify appropriate replacement options.

Selecting the right bellows solution requires understanding your specific system needs. The high flexibility rubber bellows deliver performance in demanding industries. Their ability to handle multiple movement types solves complex problems.

Manufacturing advancements continue to improve performance capabilities and durability. The engineers should evaluate existing systems for potential bellows upgrades regularly. The bellows remain critical to industrial reliability and safety. Their simple appearance masks their complex engineering importance.

Make your machinery work better with our high flexibility bellows. These essential components reduce downtime and extend equipment life. Ready to improve your industrial operations? Our team is standing by at +1(647)294-5240 to discuss your specific needs. For a custom quote tailored to your machinery, send your requirements to info@customrubberbellows.com and we'll help you find the perfect flexible solution.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.