Rubber Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

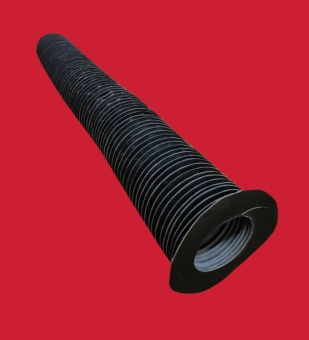

Bellow boot

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

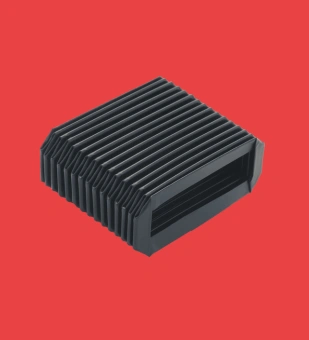

Bellow Seal

Sealing Capability

Wide Application

Pressure Resistance

Vibration Isolation

Customizable Design

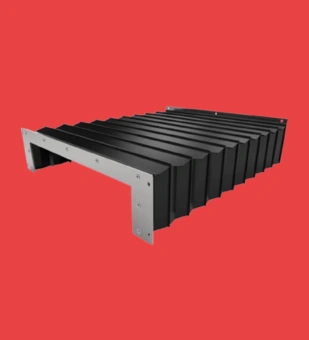

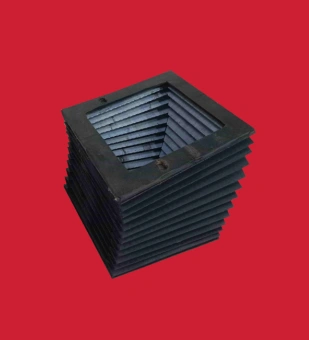

Bellow Cover

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

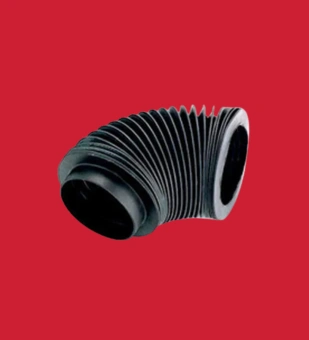

Silicone Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

Flexible Bellows

Precise Fit

Durable Material

Customizable Shapes

Leak-Proof Sealing

- Home

- C Type Bellows

What Are C Type Bellows and Where Are They Used?

The industrial systems need reliable components to handle movement and pressure changes. The C type bellows are important flexible connectors in many applications. Their shallow corrugations allow for controlled movement in tight spaces.

Many engineers choose them for their balance of cost and performance. These special metal components prevent damage from thermal expansion and vibration. Their unique C-shaped profile distinguishes them from other bellows. The materials improve their durability in harsh operating environments.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

C Type Bellows In Industry

Our Products

What Are C Type Bellows?

C type bellows are unique metal materials used to be flexible in most industrial systems. They have a unique shallow that can move and retain structural integrity. These bellows suit best those systems that require dependable expansion joints. They are designed in a way that they can compress and extend into the tight space in the axial direction. Most of them are manufactured using stainless steel or other alloys to help counter corrosion.

- The convolution walls have a thickness of 0.3-0.8 mm

- Temperature operation range: between -50 °C to 650 °C

- The standard size goes as low as 25mm to 3000mmservice life of between 5-15 years

- The pressure rating varies between holding up a vacuum and 25 bar

The production is done by an accurate shaping by hydraulic or mechanical process. The pressed metal sheets are made in the characteristic C-profile. The corrugation is done so as to have an even distribution of movements.

The custom C type rubber bellows provide additional protection in harsh environments. They're often installed as protective covers over metal bellows in chemical plants.

The standard C-type configurations include end fittings welded directly to the bellows unit. This integrated design creates a leak-proof seal for fluid systems. The engineers select specific designs based on anticipated movement requirements and operating conditions..

| C Type Bellows Specifications Table | |

| Specification | Typical Values |

| Material | SS 304, SS 316, Inconel 625 |

| Wall Thickness | 0.1 mm to 0.5 mm |

| Convolution Depth | 3 mm to 12 mm |

| Diameter Range | 25 mm to 3000 mm |

| Pressure Rating | Up to 10 bar |

| Temperature Range | -50°C to 550°C |

| Ply Count | 1 to 3 plies |

| Movement Type | Axial, limited lateral |

Design Features of C Type Bellows

The defining characteristic of these components lies in their convolution shape. The C-types offer reduced spring rates and flexibility. Their light profile allows them to perform effectively in small areas. The industrial C type bellows manufacturers concentrate on precision engineering in order to secure reliable performance.

1. Structural Configuration

C-type designs may either be manufactured as single-ply construction or multi-ply. Single-ply versions are best for low pressure applications with minimal stress. Multi-ply configurations provide enhanced durability for demanding conditions with pressure fluctuations. The number of convolutions influences the number of units of the overall movement capacity.

2. Material Selection

The material selection influences the performance capability and service environment. The 304 and 316L stainless steel are still used in general. The inconel offers superior performance in high-temperature settings above 500°C. The flexible C type silicone bellows provide alternatives where extreme temperature variations occur. They maintain elasticity across a wider temperature range than metal varieties.

3. Manufacturing Methods

The production techniques vary depending on the required specifications and material properties. The hydroforming creates controlled convolutions through liquid pressure against die surfaces. Mechanical forming is a process that involves rollers and presses in shaping metal sheets to create bellows. The quality aspect consists of high standards of testing of movement capacity, spring rate and integrity of pressure.

Countries

Industries Served

Projects

Clients

Where Are C Type Bellows Used?

The flexible components are used in most industries that need flexible connections. They can be used in solving difficult issues when a firm pipe cannot be moved about because it would not work. The high durability C type expansion bellows are used for important purposes in power generation facilities. They compensate for thermal expansion in steam lines.

1. Energy Sector Applications

Power plants use these bellows throughout their steam generation systems. They absorb thermal growth in piping networks that reach temperatures exceeding 500°C. Nuclear facilities rely on special variants with enhanced radiation resistance. The solar thermal plants include them between collector sections and heat exchangers.

2. Industrial Processing Systems

The chemical processing facilities depend on C-type bellows for handling corrosive media. The petrochemical refineries use them at critical junctions. The paper mills install these components in steam distribution networks throughout production areas. Mining operations use them in slurry transport systems.

3. Building Services Integration

HVAC systems include these bellows as expansion joints in large ductwork. They prevent thermal stress from damaging air distribution systems in commercial buildings. The chilled water circuits use them to absorb pump vibration and thermal movement. The rubber C type bellows covers provide additional insulation and protection in visible installations.

4. Transportation Infrastructure

Marine vessels use these components in engine exhaust systems to prevent damage. They accommodate the constant movement experienced in rough sea conditions. The railway systems incorporate them into pneumatic braking systems for reliable operation. Aircraft ground support equipment uses special versions for fuel transfer systems.

Benefits of C Type Bellows

These components have advantages compared to alternative flexible connectors. Their simple design allows for cost-effective production in large diameters. The installation requires less special equipment than more complex expansion joints.

The compact length of C-type bellows creates space savings in tight installation areas. This proves valuable in retrofit projects where available room remains limited. Their lightweight construction reduces support requirements and installation complexity.

The standard units deal with the axial movement and ensure the integrity of a system. They are designed to isolate vibration which can otherwise destroy equipment connected to the motor.

Material Flexibility, System Efficiency, and Application Suitability

Material versatility is another major advantage of the C-type design. The manufacturers can produce them from virtually any malleable metal or suitable elastomer. This ensures compatibility with nearly all process media and environments. The engineers can select the ideal material combination for specific operating conditions.

The relatively low spring rate compared to other bellows styles reduces anchoring requirements. This characteristic translates to less complicated piping system designs overall. The installation costs decrease, and system reliability increases through proper application.

These bellows provide solutions for moderate pressure applications across industries. Their balance of cost, performance and availability makes them engineering favourites.

The components' shallow convolution profile makes them ideal for specific industrial needs. The metal processing facilities rely on their ability to absorb movement. The chemical plants appreciate their compatibility with various process media. C type bellows will continue evolving to meet changing industrial demands. These essential components will remain industrial mainstays for decades.

Our C Type bellows are perfect for special uses where space is tight or movement is unusual. Made with care from top materials, they work well and last a long time. To learn more about C Type bellows and how they can help your machines, call us today at +1(647)294-5240 or write to info@customrubberbellows.com.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.