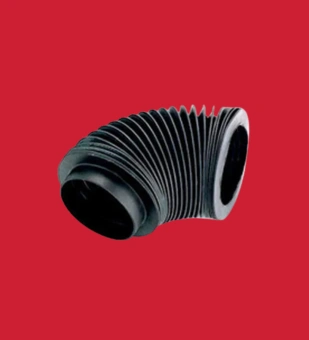

Rubber Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

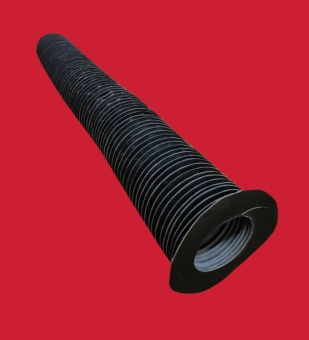

Bellow boot

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

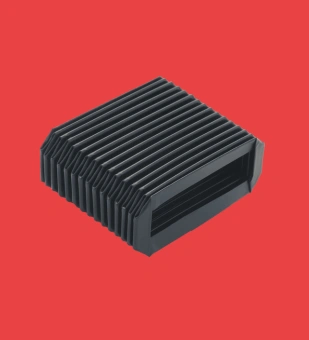

Bellow Seal

Sealing Capability

Wide Application

Pressure Resistance

Vibration Isolation

Customizable Design

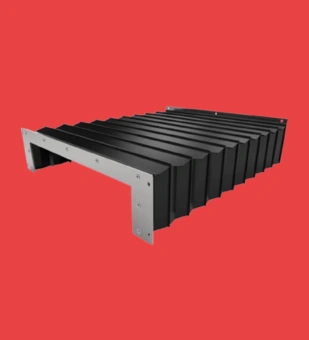

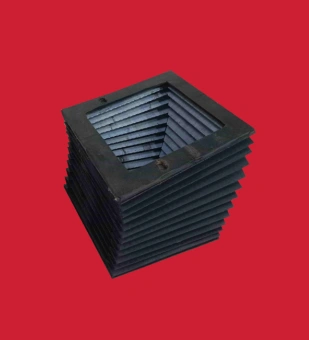

Bellow Cover

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

Silicone Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

Flexible Bellows

Precise Fit

Durable Material

Customizable Shapes

Leak-Proof Sealing

- Home

- Circular Bellows

Circular Bellows Manufacturing Process: Material, Molding, and Testing

The engineering world relies heavily on flexible mechanical connectors for countless applications. Circular bellows serve as vital components in modern industrial systems. These accordion-shaped parts absorb movement and maintain perfect seals against liquids and gases.

Manufacturing companies produce these components for pumps, valves, and aerospace equipment. These special parts must withstand harsh conditions for many years. Their ability to compress, expand, and bend makes them uniquely valuable. The manufacturing process combines material selection with advanced molding techniques.

We'll discuss material options ranging from stainless steel to special rubbers. The forming methods differ between metal and elastomer versions.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Circular Bellows In Industry

Our Products

What Are Circular Bellows?

Circular bellows are mechanical parts that are expected to flex and not break. They provide protection against dust, changes in pressure and undesirable vibration on delicate equipment.

These versatile components come in various sizes depending on their use. The small versions measure just 10mm in diameter for precision instruments. The huge industrial designs have the capability of reaching 500mm across heavy machinery.

The production of these components is a sensitive task and a tedious matter of choosing materials. It is produced with special equipment and professional technicians on each of the production stages. These flexible connectors have been used in many industries with critical applications.

- Fill piping systems with thermal expansion

- Decreased noise propagation among the attached components

- Compensate for mechanical assemblies that are out of tolerance

- Use in rotating machines as covers over their shafts

- Movement amid stationary points permitted

Materials Used in Circular Bellows

The material selection influences performance and endurance in a hostile environment. The traditional custom circular rubber bellows provide customized solutions to the needs of the application. Various materials present different properties that are appropriate in different operating conditions. The manufacturers choose a material depending on the range of temperature and chemical exposure.

1. Metal Options

The stainless steel types 304 and 316 resist corrosion in wet environments. These alloys maintain integrity even when exposed to many chemicals. The inconel is the best for the extreme heat conditions and can reach up to 1000°C. The phosphor bronze provides spring-like qualities for repeated flexing cycles.

2. Elastomer Choices

The nitrile rubber stands up well against oils and petroleum products. This material retains flexibility across moderate temperature ranges with minimal degradation. The silicone performs from freezing to 60°C up to baking at 200°C. EPDM resists weather damage, ozone exposure, and ultraviolet radiation.

3. Selection Considerations

The engineers must balance cost against performance requirements for each application. The material options used in long-term installations are affected by their predicted lifetime cycles. The chemical resistance becomes crucial when handling harsh substances in industries. Any temperature fluctuations can cause premature failure.

| Common Defects and Prevention | ||

| Defect | Cause | Prevention |

| Cracks in convolutions | Over-stretching during forming | Control forming pressure |

| Uneven wall thickness | Poor mold alignment | Regular mold calibration |

| Surface porosity | Air trapped in rubber | Vacuum-assisted molding |

| Weld leaks (metal) | Incomplete fusion | Optimize weld parameters |

| Early fatigue failure | Wrong material choice | Match material to application |

Countries

Industries Served

Projects

Clients

Molding and Forming Methods

The industrial circular bellows manufacturer uses various methods depending on materials and specifications. The forming process differs significantly between metal and elastomer versions.

1. Metal Forming Techniques

The hydroforming uses water pressure to shape metal tubes into precise patterns. This method creates uniform wall thickness throughout the entire component. The roll forming uses rollers that gradually press flat metal sheets. The edge welding joins thin metal discs at their inner and outer edges.

2. Elastomer Molding Processes

The compression molding is the pressure placement of raw rubber into a heat mold under pressure. During the curing process, the liquid mass is that which is flowing and forming at temperatures of approximately 165 °C.

The injection processes cause liquid rubber compounds to be introduced into the cavities molds quickly. Transfer molding forces the rubber into the final molds previously shaped.

3. Finishing Operations

After the initial forming, parts require careful trimming and inspection. The flash removal eliminates excess material that is squeezed between mold sections. The surface treatments enhance corrosion resistance for metal components after annealing.

Some flexible circular silicone bellows receive special coatings to reduce friction. These elaborations make sure that it has good operation in the tough applications.

Testing and Quality Control

Strict testing ensures components meet strict performance and safety standards. The high durability circular rubber bellows undergo multiple inspections throughout production. The testing protocols verify dimensional accuracy and functional capabilities under stress. These quality checks are there to detect defects as the products are being shipped to the customers.

- Dimensional Verification: The fine measurements verify that there is no inner and exterior desired mismatch between inner and outer diameter. Wall thickness influences flexibility, which has to be the same everywhere. Special measuring equipment is used to test the convolution pitch uniformity by the inspectors. Any minor differences may affect the performance of vital applications.

- Performance Evaluation: The pressure testing exposes the samples to a 1.5-fold working pressure. This verifies safety margins and identifies potential weak points. Leak detection uses helium or bubble testing methods for airtight components. The circular expansion bellows must maintain seals and accommodate movement.

- Durability Assessment: The cycle testing replicates real use by flexing components thousands of times. The machines record exactly when and how samples eventually fail. Extreme temperatures and conditions of chemical exposure are replicated in environmental chambers. Hardness, tensile strength and elongation are confirmed by testing of materials.

The manufacturers document test results for quality assurance and certification purposes. These records provide traceability throughout the product lifecycle. These testing data are used to advance these processes of improvement. The information helps engineers refine designs for better performance.

The circular bellows represent a perfect blend of engineering precision and practical function. Many advances will allow for predictive maintenance before catastrophic failures. Manufacturing facilities increasingly adopt sustainable practices in production processes. The knowledge gained from decades of development benefits many industries.

For details about our making process or to order custom circular bellows, call us at +1(647)294-5240. You can also write to info@customrubberbellows.com for more information and a price quote.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.