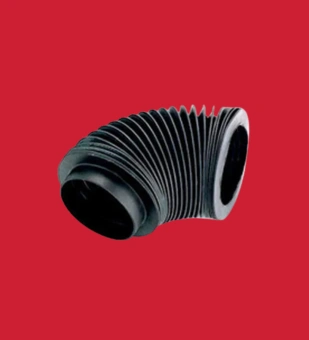

Rubber Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

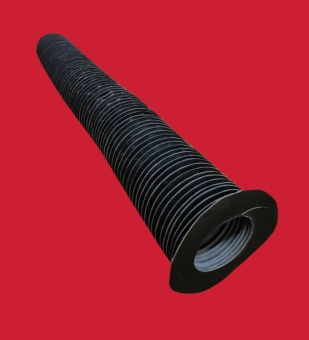

Bellow boot

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

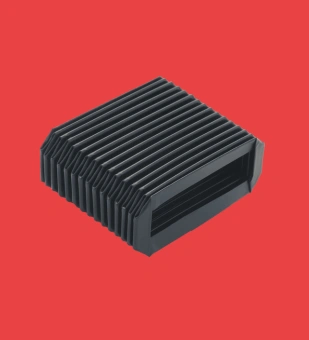

Bellow Seal

Sealing Capability

Wide Application

Pressure Resistance

Vibration Isolation

Customizable Design

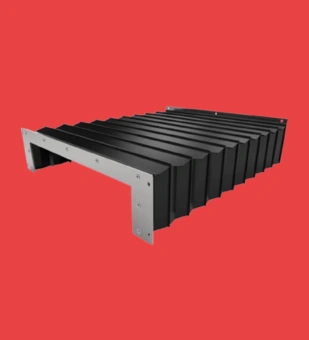

Bellow Cover

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

Silicone Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

Flexible Bellows

Precise Fit

Durable Material

Customizable Shapes

Leak-Proof Sealing

- Home

- Hexagonal Bellows

Main Benefits of Hexagonal Bellows in Industrial Machines

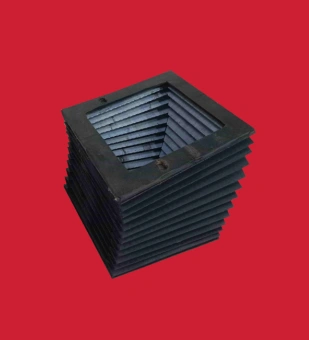

The industrial machinery needs proper protection for peak performance. The mechanical part is taken by a hexagonal bellows to protect the mechanical components in harsh conditions. These shield covers are six-sided and flexible, and move with the machine parts. The unique design blocks contaminants and allows a full range of motion.

The special six-sided structure creates tight seals at every fold. Each corner provides an additional barrier against unwanted materials. The materials enhance their performance in extreme temperatures and conditions.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Hexagonal Bellows In Industry

Our Products

| Specifications Table | |

| Feature | Details |

| Shape | Six-sided hexagonal |

| Material | Nylon fabric, polyester, PVC |

| Temperature Range | -40°C to +120°C |

| Extension Ratio | Up to 1:10 |

| Thickness | 0.3 mm to 0.8 mm |

| Mounting Style | Flange, clip, adhesive |

| Standard Colors | Black, grey, silver |

| Lifespan | 3 to 7 years average |

| Water Resistance | IP54 to IP65 rated |

| UV Resistance | Available on request |

What are the Key Benefits of Hexagonal Bellows?

1. Superior Dust Protection

The machines perform better when their moving parts stay clean. Hexagonal bellows create tight seals to block fine dust particles from getting inside. The unique six-sided design forms sharp corners at each fold point. These corners make an ideal barrier against even microscopic debris. Most traditional bellows leave small gaps where dust sneaks through over time.

The factories generate particles that damage precision components. The tightly folded structure catches these particles before they reach sensitive areas. The internal parts maintain their smooth surfaces without abrasion damage.

The production lines, when dust protection is done properly, are hardly likely to have any unexpected downtime. The clean rails are smooth and move without jerks or resistance.

- Removal of the practice of microscopic particles on the moving parts

- Establishes several barrier points at every corner intersection

- Cuts down the cleaning frequency by almost 70% where the dust is a problem

- Sustains quality performance in the powder-processing plants

- Reduces unexpected service repair measures

2. Chip and Debris Shield

Metal cutting operations create flying debris that damages machines. The custom hexagonal rubber bellows deflect these sharp fragments away from critical parts. The rubber material absorbs impacts without tearing or puncturing easily. Many machine operators feel safer when dangerous chips can't reach them.

The CNC machining centres benefit from proper debris protection. The six-sided design traps metal fragments in its folds before they travel. The guide systems remain precise because no foreign objects interfere with alignment. The quality remains the same when machines run smoothly without obstructions.

Installing proper shields prevents costly repairs from accumulated damage. The rubber construction withstands thousands of impacts during normal operation. The engineers can focus on optimisation instead of worrying about machine protection.

- Captures up to 95 per cent of metal chips before sensitive mechanisms

- Remains strengthened against repeated impacts

- Makes natural routes through which the debris falls onto the machine

- Dilutes the danger of being hit by flying metal fragments

- Applications to wet cutting and dry cutting

Countries

Industries Served

Projects

Clients

3. Compact Folding Design

The industrial hexagonal bellows manufacturer focuses on minimising the footprint when compressed. The six-sided geometry creates flat, neat stacks between machine movements. The compact machines fit in smaller spaces while maintaining full functionality.

Short stroke applications benefit from hexagonal folds. The bellows compress nearly flat against themselves when not extended. Many designers can create more compact machines without sacrificing protection quality. Space savings of 40% compared to circular bellows aren't uncommon.

The stacking pattern remains consistent through thousands of operation cycles. The production lines can place equipment closer together without interference issues. The compressed profile stays thin even after years of use.

- Achieves compression ratios 1:10 in most applications

- Repeated folds with millions of cycles

- Cuts down on total machine footprints by 40 per cent

- Establishes some predictable patterns of movement among machine designers

- Tighter production line designs are possible

4. High Flexibility Range

The flexible hexagonal silicone bellows stretch impressively while maintaining protective properties. Their design allows for extension up to ten times their compressed length. Machine axes move freely without feeling resistance from their covers.

The silicone materials provide elasticity in many environments. The flexibility remains consistent in both hot and cold operating conditions. The designers can create machines with complex motion requirements confidently. Any movements happen smoothly without catching or binding issues. These covers should never limit machine performance capabilities.

Machines move more naturally with properly matched flexibility characteristics. The silicone composition stretches evenly across all six sides. Motion systems experience minimal drag during rapid position changes. The operations maintain their accuracy with properly designed protection.

- Maintains protective integrity and extends to 10x compressed length

- Performs consistently between -40°F and 400°F (-40°C to 204°C)

- Provides smooth movement with under 0.5% resistance force

- Accommodates multi-directional motion without binding or twisting

5. Coolant and Oil Resistance

The high strength hexagonal expansion bellows resists degradation from industrial liquids. The cutting fluids, coolants, and lubricants don't penetrate properly designed bellows. The guide systems remain dry even during heavy coolant application.

The material composition is necessary for chemical resistance. The advanced formulations prevent oil absorption that weakens standard covers. The lubricants do not move but remain in the right position.

The tests are long-term exposure tests which show the survivability of the product in adverse conditions. Hexagonal rubber bellows cover materials maintain strength after years of contact. The manufacturers replace these protective elements less frequently than alternatives. The resistance properties don't diminish over the operating lifetime.

- Resists breakdown from cutting oils, coolants, and water-based fluids

- Prevents fluid migration into sensitive electronic components

- Maintains seal integrity after 5+ years of continuous exposure

- Doesn't absorb or swell when contacted with industrial chemicals

- Meets environmental containment regulations for industrial fluids

The bellows deliver good performance in many industrial applications. The processes of the new manufacturing produce more accurate folds with a high level of tolerance. The advanced compounds are not subject to extreme cold and heat.

Many custom solutions address specific challenges in special manufacturing environments. The engineers recognise the design elegance in solving multiple problems. The machines perform best when properly shielded from harsh operational environments.

Our hexagonal bellows offer better protection and longer life for your industrial machines. To see how our hexagonal bellows can help your business, call our team at +1(647)294-5240. You can also send an email to info@customrubberbellows.com for more details and to get a custom price quote for your needs.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.