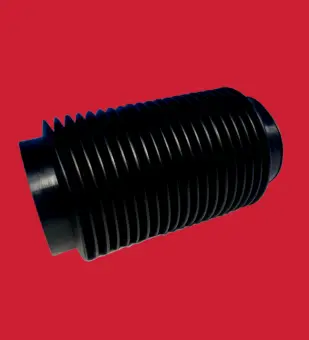

Dust Protection Bellows

Leak-Proof Seals

Easy Maintenance

Pressure-Resistant Seals

High-Temperature Resistance

Long-Lasting Performance

- Home

- Dust Protection Bellows

Silicone vs Rubber Dust Protection Bellows: Choosing the Right Material for Industry

The manufacturers need to keep machine parts clean and functional. The protective coverings play a vital role in extending equipment life and reliability.

The rubber dust protection bellows prevents unwanted particles from reaching sensitive mechanical components. These flexible barriers create a shield against many environmental contaminants. It is a decision on whether to use silicone and rubber that affects the total performance and durability.

Many industrial environments expose machines to extreme environments that hasten the process of wear. The companies need to select the proper protective barriers to prevent costly breakdowns and production delays. The material offers specific benefits. The temperature ranges, chemical exposure, and movement requirements affect material selection.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Dust Protection Bellows In Industry

Our Products

What Are Dust Protection Bellows?

The machines are to be safeguarded against the destructive factors in hard conditions. The industrial dust protection bellows shields between the sensitive parts and the external pollutants. These are accordion-type covers that stretch and contract with mechanical motions and stay completely sealed. Most manufacturing facilities rely on these protective devices to extend equipment lifespan.

The flexible design allows for smooth operation during linear or rotational movements. The bellows prevent costly downtime that often happens when dust infiltrates machinery. Their accordion folds compress and expand precisely with each mechanical cycle. Many precision industries find them mandatory and not optional.

- Minimise microscopic particle-induced premature bearing failure

- It lessens the costs of maintenance considerably throughout the equipment's life

- Special sizes available in specially made sizes

- Offer the reduction of noise benefits in certain installations

- Retrofits to old equipment to offer more protection

Rubber Dust Bellows- Properties.

The natural rubber compounds are found to render unmatched resilience under tough circumstances. The composition material consists of EPDM, neoprene or nitrile. The rubber dust protection bellows can tear extremely well, even in instances of being exposed to sharp metal chips. Their mechanical durability makes them ideal choices for heavy machinery applications.

The cost considerations often favour rubber options for many industrial implementations. The material handles repeated compression cycles without losing structural integrity. Nitrile varieties excel when exposed to fuels and lubricants in automotive environments. EPDM formulations resist weathering effects that would degrade other materials quickly.

The rubber bellows are flexible within a range of temperatures considered moderate without cracking. The steelwork is heavier in nature, which adds extra measures against puncture by flying debris. The material is popular in industries that require continuous vibration and stress. The production processes for rubber bellows require less special equipment than alternatives.

| Comparison Table – Silicone vs Rubber Bellows | ||

| Property | Silicone Bellows | Rubber Bellows |

| Temperature Range | -60°C to +230°C | -40°C to +120°C |

| UV/Ozone Resistance | Excellent | Moderate (EPDM is better) |

| Tear Resistance | Low to moderate | High |

| Abrasion Resistance | Moderate | High |

| Flexibility | Excellent at all temps | Stiffens in cold |

| Chemical Resistance | Moderate | Varies by rubber type |

| Oil/Fuel Resistance | Poor | Good (nitrile best) |

| Food/Medical Safe | Yes (FDA grades) | Limited options |

| Cost | Higher | Lower |

| Lifespan (Outdoor) | Long | Moderate |

| Weight | Lighter | Heavier |

Silicone Dust Bellows – Properties

The advanced manufacturing processes produce flexible silicone dust protection bellows with exceptional temperature resistance. These components remain pliable even in extreme colds that would make rubber brittle. The silicone compounds maintain their protective properties from -60°C up to scorching 230°C environments. The molecular structure allows elasticity throughout this impressive range.

Many medical and food processing industries value silicone for its non-reactive properties. The lightweight construction reduces strain on moving parts in precision machinery. Many cleanroom operations specify silicone exclusively due to low particle generation. Many custom dust proof bellows manufacturers offer special formulations for sensitive environments.

The UV and ozone exposure barely affect high-quality silicone compared to alternatives. The material costs more initially but often provides longer service in harsh conditions. The temperature cycling rarely causes deterioration even after thousands of operational cycles. The food-grade versions can contact consumable products safely and maintain protective functions.

Countries

Industries Served

Projects

Clients

Factors to Consider Before Buying

The right material needs careful analysis of operational conditions. The dust protective rubber expansion bellows excel in environments with mechanical stress and abrasion. The initial investment affects long-term ownership costs through replacement frequency and downtime. The material selection influences overall equipment protection effectiveness.

The forms of exposure to the chemical must be used to determine the best material to use. Severe local climate conditions at the sites of installations restrict the material that can be used. The rate and magnitude of movement affect the rate at which materials become fatigued. Many special applications require custom solutions rather than standard catalogue products.

Challenges Faced by Industries

Different industries face unique challenges that influence the bellow selection. Automotive manufacturing requires oil resistance and heat stability. Pharmaceutical production demands materials that generate minimal particles and accept sterilisation. Electronics manufacturing needs static-dissipative properties to protect sensitive components. What can clients can do:

- Consider potential chemical interactions with surrounding equipment

- Evaluate necessary flame-retardant properties for some applications

- Assess the required compression ratio for the available installation space

- Determine the required colour coding for safety or identification

- Verify material compatibility with existing components

The investment in quality bellows prevents expensive repairs and unwanted downtime. Manufacturers continue developing new compounds with enhanced protective properties. Their regular inspection helps identify early signs of wear before failure. The installation quality affects how well these protective barriers perform.

Many special applications require custom solutions rather than standard products. The industrial sector demands long-lasting protective components.

Get the right material for your dust protection bellows. Call us at +1(647)294-5240 to discuss your dust protection requirements. For detailed material comparisons and pricing, email your specifications to info@customrubberbellows.com and we'll guide you to the best solution.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.