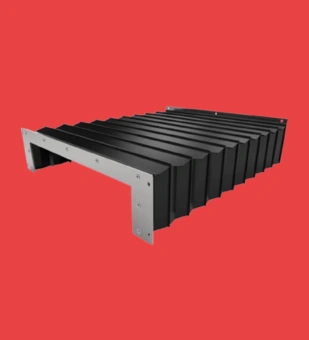

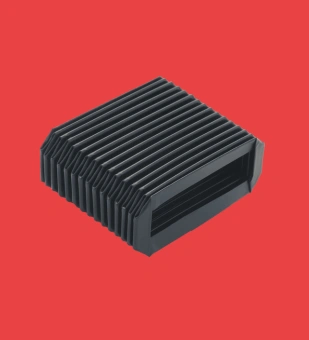

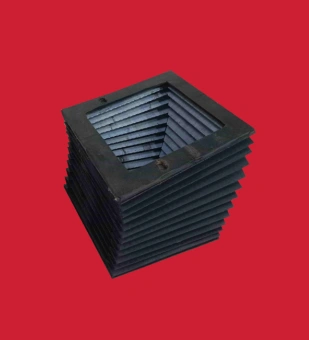

Rectangular Bellows

High Durability

Shock Absorption

Heat Resistance

Enhanced Insulation

Reliable Performance

- Home

- Rectangular Bellows

How Industrial Rectangular Bellows Protect Linear Motion Systems?

Modern manufacturing equipment faces daily battles against harsh environments. The metal chips, dust, and coolant constantly attack sensitive components in linear motion systems. These precision parts quickly deteriorate when left exposed to workshop conditions.

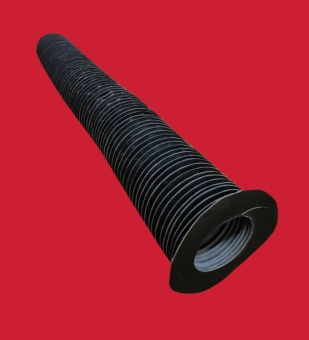

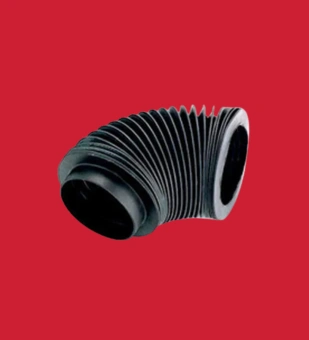

The rectangular bellows create a flexible barrier that moves with the machine. This solution covers vulnerable rails, ballscrews, and guideways from contamination. The accordion design allows full motion while maintaining complete protection throughout. It is used in CNC machines, robots, and automated systems.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rectangular Bellows In Industry

Our Products

What Are Industrial Rectangular Bellows?

Rectangular bellows protect machine components and allow necessary movement.The accordion-style covers provide good resistance to dangerous components in the harsh factory conditions.

The vast majority of models are forced to compress during machine use, with a common 10:1 compression when fully collapsed. They have a cross-sectional shape in the form of a rectangle to supplement the linear motion systems of industrial equipment.

The materials depend on certain uses and other needs of the environment. Bellows are made with heavy-duty fabrics reinforced with synthetic material in order to be durable. Others contain leather parts against hot metallic chips. The latest models have developed composites. This is able to resist chemicals and be flexible enough to pass thousands of cycles.

Installation of Industrial Rectangular Bellows

The installation is custom-fitting and therefore provides appropriate protection. The engineers will take the exact size of the application, then measure it prior to production. This will ensure that vulnerable components are well covered. The motion-based application is safeguarded by the following:

- Protect sensitive electronic parts against conductive particles

- Avoid wear on bearings and guidesCreate cleaner workplaces

- Minimise machine operation noise

- Adhere to safety requirements on the moving parts

How Do These Bellows Protect Against Contaminants?

The custom rectangular rubber bellows create an effective barrier against these harmful elements. Their flexible design allows full movement and maintains complete coverage. The machine operators report cleaner components after installing proper protective bellows. This protection ensures few breakdowns and long intervals for servicing and replacements.

1. Solid Particle Protection

The metal shops generate abrasive particles that damage sensitive components. They can grind the dust into guide rails. This causes premature wear and binding. The sharp metal chips from cutting operations can scratch polished surfaces.

The weld spatter presents a challenging threat due to its heat and hardness. Environmental dust accumulates on horizontal surfaces throughout facilities. The bellows stop these particles before they reach critical components.

2. Liquid Contaminant Defence

The manufacturing relies on various fluids that threaten precision equipment. The abrasive particles are suspended in the moisture of the coolant splash of adjoining operations. The lubricating spray leaves residues which attract other contaminants.

Any kind of exposure to water causes corrosion problems on the surfaces that are not properly protected. Chemical processes release aggressive fluids that attack even stainless components. The flexible rectangular silicone bellows provide resistance against these liquid threats without degrading.

3. Thermal Protection Solutions

The hot chips generated during cutting can melt standard protective covers. The heat from nearby processes gradually weakens many materials. Sparks from grinding and welding operations cause pinhole damage to lesser coverings.

The thermal-resistant bellows materials maintain their protective properties despite these challenging conditions.

Countries

Industries Served

Projects

Clients

Impact on Linear Motion System Performance

The high durability rectangular expansion bellows improve system reliability through contamination control. The technicians report substantial progress after proper installation. Most companies experience a few emergency repairs and consistent production schedules.

The positioning accuracy benefits cannot be overstated for precision applications. The small particles between bearing surfaces create deviation from programmed paths. These errors compound over time, resulting in rejected parts.

The bellows maintain precision throughout the operational periods. Measuring equipment verifies this consistency in production environments.

The clean grease maintains its intended properties much longer than contaminated lubricants. This extended service reduces maintenance frequency. The engineers also use less time servicing the safeguarded equipment and more time in productive activities.

| Material Properties That Enable Protection | ||

| Property | Function | Benefit |

| Abrasion Resistance | Withstands chip impact | Long service life |

| Oil Resistance | Repels cutting fluids | No material breakdown |

| Heat Tolerance | Handles hot debris | Safe up to 150°C+ |

| Flexibility | Allows smooth motion | No drag on system |

| Tear Strength | Resists punctures | Maintains seal integrity |

| UV Stability | Resists light damage | Outdoor use possible |

| Anti-Static | Prevents dust attraction | Clean operation |

| Water Repellent | Blocks moisture entry | Corrosion prevention |

Design Features for Enhanced Protection

Most major industrial rectangular bellows manufacturers provide many special features. Their designs have been able to deal with certain problems which arise during the application through innovative solutions.

The engineers strike a fine balance between protection and movement requirements as well as cost concerns. The most successful designs often have multiple protective strategies.

1. Frame Construction Principles

The internal structure provides essential support for the flexible bellows material. The steel frames offer maximum rigidity for demanding applications with forces. The plastic internal supports provide light weight options for faster-moving systems.

PVC stiffeners maintain the rectangular shape through thousands of cycles. The folds ensure proper compression without binding or wear points. The frame design determines both the protection level and operational lifespan.

2. Connection Methodologies

Securing the bellows to the machine creates the critical seal against contaminants. Clamping flanges provide quick installation and removal for maintenance access. The bolt-on end plates create more permanent attachments for static applications.

The Velcro attachment strips allow quick replacement in less critical areas. The rectangular rubber bellows covers include mounting features for secure attachment.

The advanced designs include additional features for enhanced protection and longevity. Any special coatings improve chemical and thermal resistance where needed. These provide protection even under the most demanding conditions.

Protecting precision equipment makes good business sense for any operation. Many companies report improvements after installing proper protection systems. The engineers now create custom configurations for virtually any application need. They prioritise these protective measures from the start.

Keep your linear motion systems safe with our tough rectangular bellows. You can call us at +1(647)294-5240. You can also email us at info@customrubberbellows.com to ask questions or get a price just for you.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.