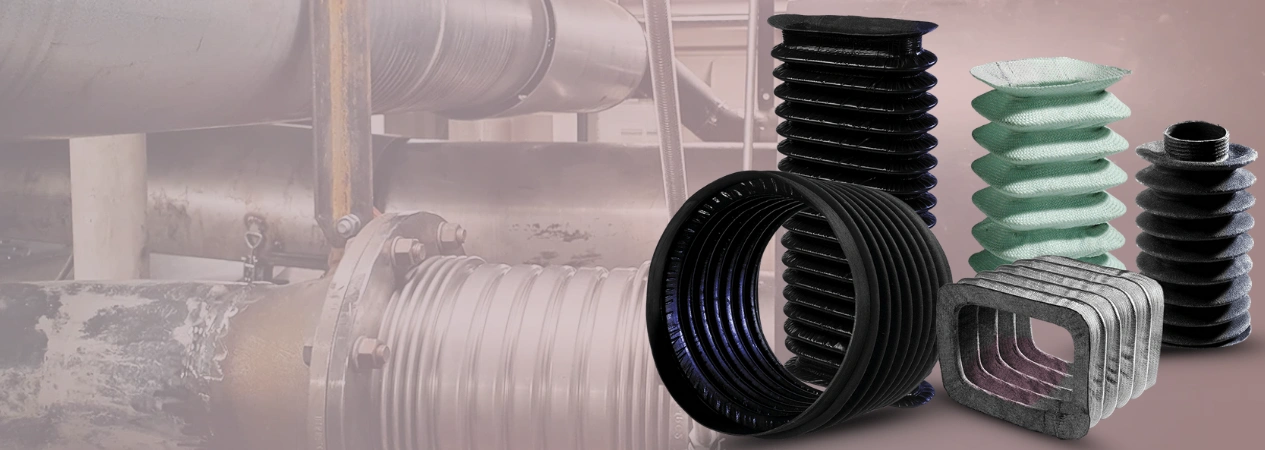

Industrial Machinery Bellows

Leak Prevention

Efficient Sealing

Vibration Control

Durable Performance

Temperature Resistance

- Home

- Industrial Machinery Bellows Manufacturer

How Machinery Bellows Manufacturers Handle Custom Designs?

The custom solutions for industrial machinery bellows have become essential. Our clients often face unique challenges that require custom approaches to bellows design. The process demands close teamwork between our experts and client teams.

Many factors impact the success of custom bellows projects over time. The right design choices early on prevent costly fixes. Our team guides customers carefully and efficiently at every step.

Most machinery faces unique stress points and movement patterns every day. These special needs can't be met with basic catalogue parts. We take time to learn about each client's exact working conditions.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Rubber Bellows Solutions with Proven Expertise

1395 projects & 690 happy clients.

At Custom Rubber Bellows, our focus is on designing and manufacturing bellows products specifically designed to meet the individual needs of each of our customers. We have a decade of experience in the industry, during which we've successfully delivered over 1395 projects for a wide range of industries, and are proud to have served more than 690 happy clients.

We customised every bellows to meet your exact requirements, guaranteeing durability, dependability, a perfect fit, and top-notch performance. Whether it's for the automotive, oil and gas, construction, chemical, or general industrial sectors, our products are made with precision to handle the toughest conditions.

5+

Countries

11+

Industries Served

1395+

Projects Completed

690+

Clients

RUBBER BELLOWS INDUSTRY

Industry Served

Why Choose Us

Initial Client Consultation and Requirement Gathering

Our process starts with intensive discussions on client needs. We meet our clients in person as it will enable us to get to know the specific needs of industrial machinery bellows and similar components.

Our engineers will inquire about the type of machine, the distance they have to move and the need to operate. We focus on gathering comprehensive details about operating temperatures and pressure requirements. Most clients aren't aware of how these factors impact bellows design and performance over time.

Environmental challenges form a crucial part of our discussion points.

We record data about:

- Exposure to dust at the workplace

- Types and risks of chemical exposures

- Moisture and humidity problems

- Patterns of vibration on the equipment

- Space-related restrictions to installation

The cycle frequency expectations help determine material durability and construction methods. When available, we collect old bellows samples to analyse wear patterns. The photos and videos of the application site provide invaluable context for our design team.

| Industries and Their Custom Bellows Needs | |

| Industry | Custom Bellows Requirement |

| CNC Machines | Protect spindles from metal chips and coolant |

| Pharmaceutical | Hygienic bellows with FDA-grade materials |

| Food Processing | Easy-clean designs with food-safe coatings |

| Steel Plants | High-heat resistant bellows for furnace areas |

| Railways | Vibration-absorbing bellows for gangways |

| Aerospace | Lightweight metal bellows for fuel systems |

| Packaging | Fast-cycle bellows for robotic arms |

| Medical Devices | Sterilizable bellows for equipment covers |

2. Design and Engineering Phase

We, as a custom machinery bellows manufacturer, leverage advanced CAD software for precise modelling. Our engineering team calculates the best fold depth and pitch depending on movement requirements. We determine the needs of stroke length when keeping the right compression ratios. The design keeps in mind the variation in the thickness of walls required at various points of pressure.

The most important one is to run FEA to identify the potential stress areas. We take these results along with client feedback to do a design modification. This approach guarantees that:

- Existing equipment matches perfectly

- The best possible combination of flexibility and strength

- Strengths material efficiency

- Selection of compatibility with mounting systems

- Performance consistency is maintained

The final drawings are subjected to very thorough reviews before approval to proceed. We do not rush this stage at all because design mistakes cause significantly increased costs further down the line. Our engineers discuss every technical detail to prevent problems during manufacturing.

3. Material Selection for Custom Bellows

We know that the material choice impacts performance longevity and operating safety. Our choice will be determined by the environment through which the rubber bellows for industrial machinery will operate.

The industrial silicone machinery bellows is flexible and resistant to temperature. These elements are very effective when regular (cyclical) movement patterns are involved. Each application has its own individual needs, which are evaluated by our material experts, and then recommendations are provided. We consider several factors during this selection phase:

- Predicted maximum and minimum range of temperatures

- The types of chemical exposure and the level of exposure

- Flexibility and compression recovery are required

- Performance without compromising budget restraints

- Stipulations that are industry-specific

Our client preferences influence our final decisions alongside technical requirements. We never select materials based solely on cost factors.

4. Prototyping and Sample Testing

Our clients receive samples of flexible machine protection bellows to check the accuracy of fittings. Prototyping phases draw out the possible problems not seen in the design stages.

We have testing processes that consist of dimensional verification using specifications. We assess movement characteristics under actual operating conditions. These tests reveal if adjustments are needed before mass production.

Our clients benefit from our thorough approach through:

- Early detection of the problems of fit

- Checking the performance of movements

- Checking of material suitability

- Possibility of demands for changes

- Belief in the quality of the end product

Written approval documents protect both parties before production scaling. This step-by-step process ensures complete satisfaction with the final product. We never skip testing phases regardless of time constraints.

5. Quality Control in Custom Production

Quality verification would help in starting a process by checking the raw materials at the point of reception. Our team conducts checks of the in-process at the various levels of production. The heavy duty industrial machine bellows is particularly tested in accordance with the usage needs.

We perform leak testing in order to verify the integrity of pressurised bellows applications. The pressure tests check the performance limits of the types of bellows made of metal. Our visual inspections catch subtle defects. Our comprehensive quality approach includes:

- Application of material certification

- Multipoint measurements of dimensional accuracy

- Flexibility testing and compression testing

- Finishing and look evaluation

- Record keeping of all tests

6. Quality Reports

We post elaborate quality reports to clients to ensure full disclosure. This will create trust and establish that we are committed to excellence. We use higher quality than what is required in the industry, so as to have a longer life.

Every custom project is handled on an individual basis. We store comprehensive documents as a reference for the future and unending advancement. We are experts and therefore our clients get the corresponding components to their machinery requirements.

Our custom-made products save money over time through longer service life. Many clients find fewer machine breakdowns after installing our tailored solutions. The value shows in less downtime and lower total cost over the years.

We stand behind our work with strong after-sales support systems. Testing results prove our custom designs outperform standard parts under demand conditions. Most clients return for future projects after seeing real-world results. Our detailed records make repeat orders smooth and quick to process. We stay current with the latest materials and making methods.

We make special bellows for machines based on what you need. Our team works with your ideas and plans to create the right size and shape. We use strong rubber that lasts long in tough conditions. Call us at +1(647)294-5240 or send a message to info@customrubberbellows.com today. Our team is ready to help you find the best solution. We can make samples first to check if they fit right.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.