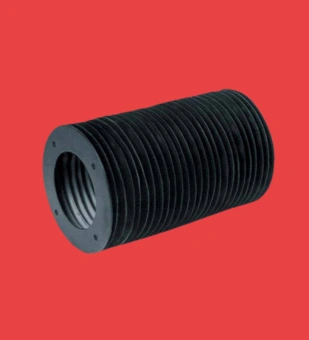

Spring Loaded Rubber Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

- Home

- Spring Loaded Rubber Bellows

Spring Loaded Rubber Bellows for Industrial Equipment: Design, Use, and Benefits

The spring loaded rubber bellows have transformed equipment reliability across many sectors. These flexible protective elements emerged from simple beginnings decades ago. The manufacturing techniques have improved their performance and durability. Many factory machines now run longer without costly breakdowns and repairs.

The production lines experience fewer interruptions due to these protective barriers. Metal springs provide protection from vibrations while rubber provides flexibility. The industrial revolution continues partly because of such practical innovations. These components represent perfect examples of function-driven design in action.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Spring Loaded Rubber Bellows In Industry

Our Products

What Are Spring Loaded Rubber Bellows?

The flexible connection system known as spring loaded rubber bellows represents one such vital element. These special tubes consist of durable elastomer materials shaped into functional protective units.

The basic design consists of a unique rubber body with outstanding flexibility characteristics. The metal coil spring is found inside this rubber cover or even outside. This spring piece provides continuous external force on the rubber walls.This type of design enables the bellows to operate reliably even under extreme duty cycles.

The bellows create an effective barrier between machine parts and harmful elements. They form dynamic seals to move along with the equipment they protect. The spring ensures proper positioning throughout the full range of movement.

Countries

Industries Served

Projects

Clients

Dynamic Protection and Sealing in Industrial Applications

Most industrial applications involve moving shafts, rods or other components. These parts need protection while maintaining their freedom of movement. The bellows expand and contract naturally with each cycle of operation. They stretch when the protected parts extend outward from the machine. Then they compress back when those same parts retract into position.

Dirt, dust, water, oil and other debris can cause significant damage. These hazardous components are effectively blocked by the flexible rubber body. It establishes some kind of protective frame around important moving components and connections. This role saves the firms thousands of dollars that could be spent on repairs. Without this protection, many industrial processes would perish soon.

The dynamic sealing function works differently from traditional static seals. They are in touch with moving surfaces at the entire extent of movement. This continuous circle prevents any impurities from entering.

Performance, Engineering Value, and Service Life Factors

The simplicity and mechanical action of these components make them valuable to many engineers. They are used to close the gap between moving parts, ensuring proper pressure. The basic principle remains the same across various implementations.

The lifespan depends largely on material quality and operating conditions. High-quality materials resist breakdown from chemical exposure more effectively. High-quality springs hold the appropriate load onger than bargain springs. The severe climatic conditions with high temperatures reduce the service life. Their periodic inspection also prevents indicators of wear failure in advance.

Here are some additional considerations about these essential components:

- The spring inside will allow it to withstand even in a vacuum environment.

- Some of them have strong parts that enhance their durability.

- Custom arrays can be used to overcome special space limitations.

- More recent materials are more resistant to UV degradation.

- Advanced production methods can ensure the width of the wall.

What are the Main Design Elements?

The design process involves balancing flexibility, durability, and functional requirements. The custom spring loaded rubber bellow represents a triumph of practical engineering principles.

1. Material Choices

Neoprene provides great protection from weather elements and ozone. It is a highly durable and resistant material that outdoor equipment can benefit from. Its environmental resistance is so high that it lasts long in operation.

EPDM polymers are stable in high-temperature conditions. It is based on the use of this heat-resistant material in the steam-intensive processes. The compound maintains flexibility even after repeated thermal cycling.

Silicone performs exceptionally well in both very high and very low temperature extremes, making it ideal for critical medical and food-grade applications.

2. Spring Types

The internal support structure determines many of the performance characteristics. The coil springs represent the most commonly used internal reinforcement. They provide reliable holding power in standard industrial applications.

Flat wire springs are used in tight space applications. They can be used in small machines since they are designed in a low profile. The space efficiency doesn't compromise the necessary holding strength.

3. Shape and Build

The external configuration impacts functional capabilities. Convoluted folds increase flexibility and extension range considerably. These accordion structures have higher movement distances.

Flat wall designs are good to use in the crowded equipment areas. The small size fits in places where the other designs fail. Without the loss of required protection, space efficiency is achieved.

The tapered end designs accommodate varying shaft diameters effectively. This versatility simplifies inventory management for maintenance departments. The adaptable fit works with different equipment configurations. Many standardised components feature this practical design element.

| Benefits of Spring Loaded Bellows | |

| Benefit | Key Points |

| Extended Equipment Life | Blocks dust, dirt, fluids; Cuts shaft wear; Prevents rust |

| Reliable Seal | Constant spring pressure; No sag over time; Works at high speed |

| Versatile Use | Fits many sizes; Wide temp range; Chemical resistant |

| Cost Savings | Less downtime; Fewer replacements; Easy install |

| Compact Design | Fits tight spaces; Lightweight; Full motion range |

| Low Maintenance | Simple design; Quick checks; Long service life |

How to Choose the Right Bellow?

The operating environment dictates many of the necessary specifications. Their careful consideration prevents costly mistakes and premature failures. Many industrial spring loaded rubber bellows function for years when properly matched to applications.

The accurate measurements ensure proper fit and function from the start. The designs of tapered ends fit different shaft sizes well. This flexibility makes inventory management easier for the maintenance departments.

Movement speed affects the optimal spring force needed. Fast-moving components require stronger spring load for proper tracking. Slower applications can use lighter spring pressure successfully. The movement pattern determines specific reinforcement requirements.

Mounting Methods, Motion Complexity, and Expert Manufacturer Support

Mounting styles include various clamp, flange, and band options. The attachment method must match the equipment design. Permanent installations often use integrated flange connections.

Some applications require special consideration for bending patterns. Side-to-side movement needs different reinforcement than linear travel. The complex motion paths require special bellows configurations. The expected movement pattern guides design selection.

Working with an experienced rubber bellows manufacturer simplifies the selection process. These specialists understand material properties and performance limitations.

The spring loaded rubber bellows continue evolving with new material science advancements. The synthetic compounds now provide better chemical resistance than earlier versions. Many manufacturing methods produce more consistent wall thickness for reliable performance.

Get the right fit for your specific needs without delays. Call us today at +1(647)294-5240 to talk with our experts about your industrial requirements. You can also email info@customrubberbellows.com for product details and a free quote. We're ready to help you find the perfect bellows solution for your equipment.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.