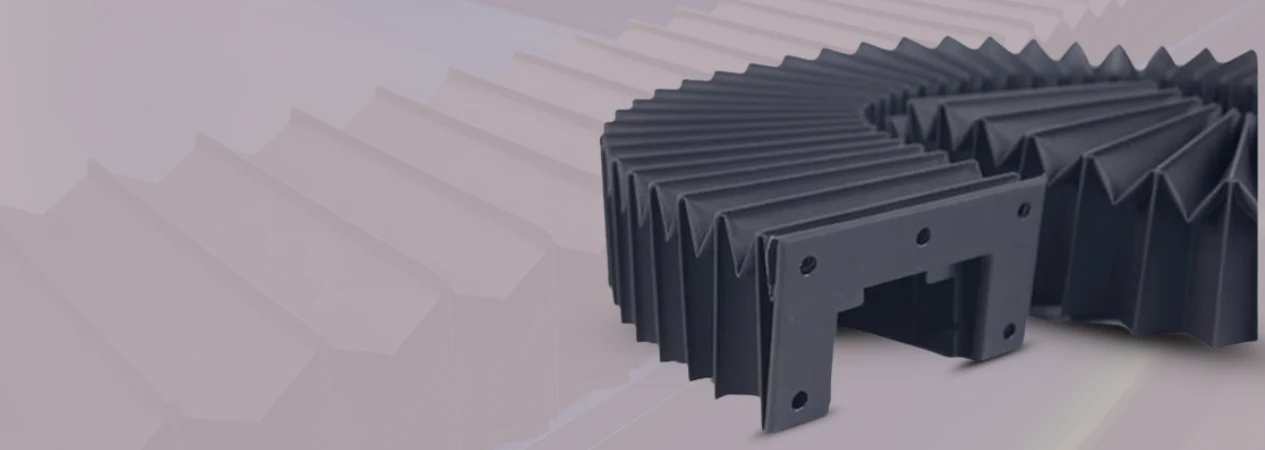

Accordian Bellows Cover

Weatherproof Seals

Leak-Free Sealing

Vibration Dampening

Custom Seal Designs

High-Pressure Resistant

- Home

- Accordion Bellows Cover

How Custom Accordion Bellows Improve Machine Life and Maintenance Cycles?

Machines face constant threats from dust, chips, coolant, and debris. The custom accordion bellows act as shields for critical components. They cover guide rails, screws, and shafts. The standard bellows often fail to fit unique machine designs.

The right accordion bellows cover prevents costly repairs and extends maintenance cycles. The operators notice fewer issues when machines have proper guards. They prioritise these simple protective measures.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Accordion Bellows Cover In Industry

Our Products

What Are Custom Accordion Bellows?

Machine parts need protection and this is where custom accordion bellows help. They fold and stretch like musical accordions and shield vital components. These covers move with the natural motion. Most are made from tough fabrics or rubber compounds. The engineers design them to match exact machine measurements.

- Do not allow debris to enter sensitive areas

- Extend and compress with the machine cycle

- The product is available in different materials depending on the environment

- Guard against wet and dry pollutants

- Minimise the maintenance frequency

The accordion bellows cover provides a mechanical obstacle to the movement of components in the harsh environment. Without proper protection, machines wear out much faster. Most industrial equipment benefits from this basic protection approach.

Threats Bellows Guard Against

The manufacturing environments create countless hazards for precision machinery. Metal chips cut through unprotected surfaces like small knives. They go into tight spaces between moving components. Once inside, they scratch polished surfaces and cause binding.

The coolant splash happens constantly around cutting machines and lathes. These liquids wash away essential lubricants from guide rails. They also cause rust when left on bare metal surfaces. The industrial accordion bellows covers block these fluids effectively. Their sealed design keeps unwanted moisture away from critical mechanisms.

The dust seems harmless, but it causes major damage over time. Tiny particles act like sandpaper on precision-ground surfaces. They gradually increase friction until components fail. Welding spatter burns through unprotected wires and hoses. It creates rough spots that catch and tear during movement.

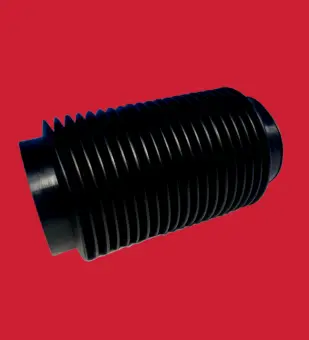

Many machines operate near hot processes in factories. The black rubber accordion bellow cover can endure higher temperatures. Its composition cannot be broken easily, even with nearby operations becoming hot.

| Custom vs Standard Bellows | ||

| Factor | Standard | Custom |

| Fit | Loose/tight | Exact |

| Gaps | Common | None |

| Life span | 6-12 months | 2-5 years |

| Protection | Partial | Full |

| Cost long-term | Higher | Lower |

Countries

Industries Served

Projects

Clients

How Custom Fit Extends Machine Life?

The general protective covers often leave gaps in coverage. The custom bellows match your exact machine dimensions and movement patterns. The flexible accordion bellows cover moves precisely with each stroke. This perfect fit eliminates exposure points where debris enters.

1. Perfect Seal, Zero Gaps

The custom bellows create complete coverage during all movement phases. The standard sizes might leave small exposed areas at full extension. These minute holes give places where the contaminants enter the system. These weak points are eliminated by the bellows. They stop being damaged in the entire span of movement.

The operators observe fewer problems with well-sealed equipment. Before the work, the bellows remain static. They never bunch up or stretch beyond their design limits. The constant coverage translates directly to fewer maintenance problems. Many operators report reductions in downtime after installation.

2. Less Wear on Internal Parts

The clean ball screws and guide rails maintain smooth, precise movement. The debris-free components require less force to operate effectively. This reduced friction means lower energy consumption during operation. The parts maintain their factory tolerances much longer. Some companies report bearing life extending two or three times.

In covered systems, the lubrication remains in its required position. The grease and oil do not go away on them. They are not polluted with environmental components. The components experience longer life spans. This reduces the frequency of replacement part orders.

3. Reduced Corrosion Risk

Moisture represents one of the biggest threats to precision machinery. Any slight surface oxidation affects movement precision. The accordion protective bellows cover prevents this moisture contact. It holds humidity and directs water off the susceptible metals.

The components retain smooth finishes and exact dimensions. This preservation maintains the tight tolerances required for precision. Machine accuracy remains consistent throughout longer operational periods.

What are Some Design Features to Boost Durability?

The bellows incorporate several features for extended service life. The reinforced edges of the folds stop tearing at the points of stress. These hardened parts withstand thousands of compressions. Many designs include internal supports to maintain proper shape. The quality bellows retain their protective abilities for years.

The end connections determine how well bellows seal against contaminants. The vulcanised connections create permanent bonds without weak points. They resist pulling away from mounting points during operation. Some custom accordion bellows manufacturers offer metal end plates. These provide superior mounting stability in harsh conditions.

The special coatings extend the service life of bellows. UV-resistant treatments prevent degradation in sunny locations. The chemical-resistant layers protect against harsh industrial solvents. Anti-static properties prevent dust buildup in certain environments.

Material Selection, Layered Protection, and Functional Design Choices

The double-layer construction provides exceptional protection in extreme environments. The outer layer handles abrasion and physical damage risks. Inner layers focus on creating effective seals against contaminants. This redundancy guarantees that the system will be operational even after it is damaged.

The choice of material is very important in the performance of bellows. Neoprene is a substance that has good properties of oil and chemical resistance. Vinyls are cheap, general-purpose shields. Silicone can resist high or low temperatures and does not crack. The manufacturers choose materials depending on some applications.

The colour combinations have a functional and safety purpose. Safety limits are visible with high-visibility colours. The dark colour conceals the dirty setting staining. Some companies match bellows to their equipment branding.

Many manufacturers report quick returns on their protection investments. The accordion bellows cover proves its value within a few months.

The quality bellows lasts for years in normal industrial environments. Their simple design hides their important role in operations. The machine replacement parts cost far more than protective coverings. Many companies save money through these preventative measures.

We manufacture high-quality bellows that work well in tough conditions. Call us at +1(647)294-5240 or send an email to info@customrubberbellows.com. Our experts will help you find the right bellows for your needs and provide a price that fits your budget.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.