Manufacturing Methods for Custom Bellows

The applications need certain methods of manufacturing in order to produce the best results.

The techniques possess distinct merits in terms of the quantity and details.

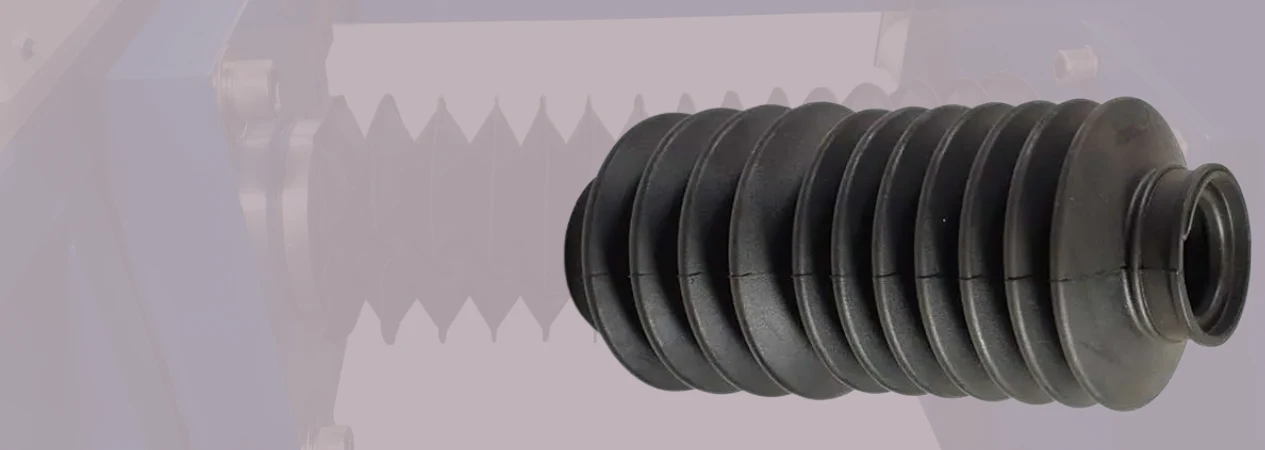

Compression Molding

The flexible bellows manufacturers in Canada often prefer compression molding for thicker applications.

This industry presses uncured rubber in hot metal molds. The technique creates stronger parts with fewer air pockets.

Heat and pressure work together to form molecules into tight bonds.

The end parts can resist tearing better than other methods.

This is best when the wall thickness exceeds several millimetres.

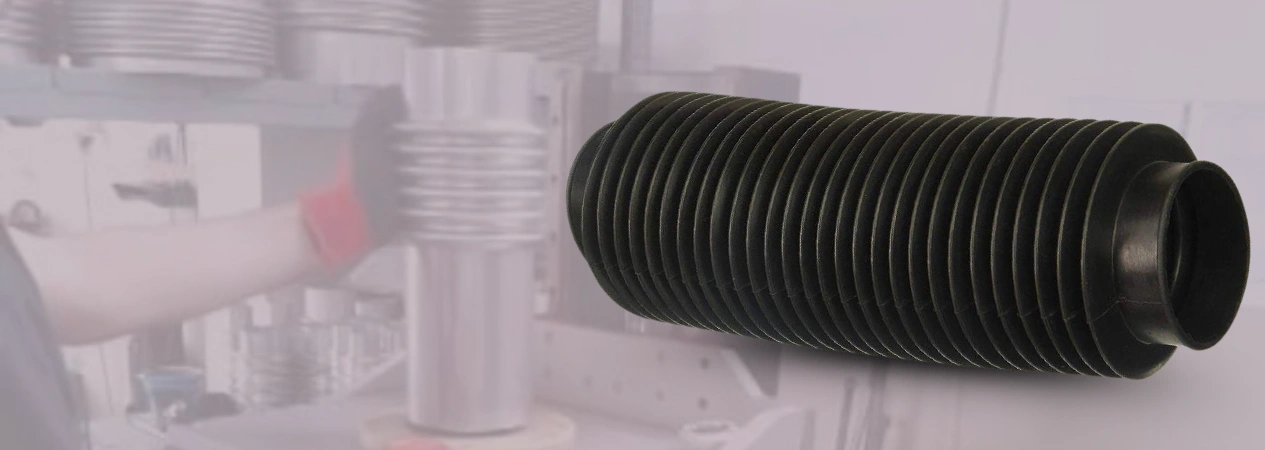

Injection Molding

The rubber bellow seal manufacturers in Canada prefer injection for high-volume production runs.

Liquid rubber shoots into molds under extreme pressure instantly.

The process maintains incredibly tight tolerances between each finished part.

Many complex shapes with internal features become possible through injection.

The multiple cavities allow for the production of several parts in a single cycle.

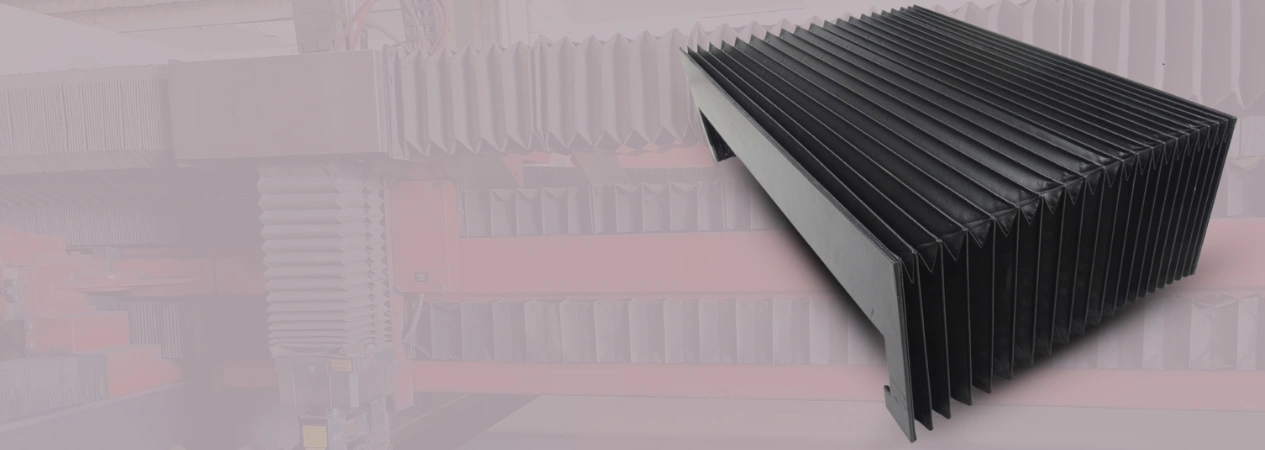

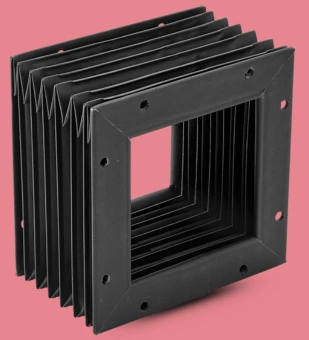

Transfer Molding

The inserts in complex shapes demand special handling methods.

The bellows boot manufacturers in Canada use transfer molding for intricate designs.

This hybrid approach combines compression and injection advantages.

Metal inserts stay perfectly positioned throughout the entire process.

The method excels when making parts with varying wall thicknesses.

- The long continuous profiles start as extruded tubes or strips.

- The hand layup performs best in extremely special, low-volume applications.

- Both methods serve important niches in custom manufacturing processes.

Rubber vs Silicone Bellows – Core Differences

The rubber bellows manufacturers in Canada provide products with distinct advantages for specific environments.

The rubber materials cost less and handle rough conditions better.

The durability factor plays a huge role when machines run constantly.

EPDM rubber is for outdoor environments with harsh weather.

Neoprene provides good resistance against oils and petroleum products.

Nitrile can resist fuels and many industrial chemicals.

Silicone is the best for extreme temperature performance without question.

The material stays flexible even at temperatures reaching -60°C.

It won't break down easily when exposed to scorching temperatures of +230°C.

Many medical and food companies choose silicone for safety reasons.

The material passes strict FDA guidelines for direct food contact.

The ageing affects silicone much less than standard rubber compounds.

- Rubber costs run 30-40% lower than silicone parts

- Most rubber compounds perform better under constant abrasive conditions

- Silicone maintains flexibility in freezing environments

- Food-grade silicone resists bacteria growth better than standard rubbers

- Chemical processing requires specific rubber formulations

Traits of a Reliable Custom Bellows Manufacturer

The silicone bellows manufacturers in Canada should demonstrate clear technical capabilities from day one.

In-house mold design capabilities save precious development time and money.

Their engineers must understand both material science and practical applications thoroughly.

The small companies often provide more attentive service on special projects.

Manufacturing facilities need clean rooms for medical-grade silicone production.

The development of their prototype suggests that they are committed to serious quality outcomes.

The fast sample products are used to detect issues in the design in advance of full-scale production.

The declarations demonstrate compliance with standards in all procedures.

Many ISO certified facilities follow documented procedures for consistent quality control.

The FDA compliance becomes critical when parts contact food or medical applications.

The testing capabilities should match the final operating conditions precisely.

The direct conversations eliminate confusion that happens through multiple channels.

The established manufacturers propose what is better using previous similar projects.

It is guided by material selection, which avoids expensive failures.