Surface Treatment Methods

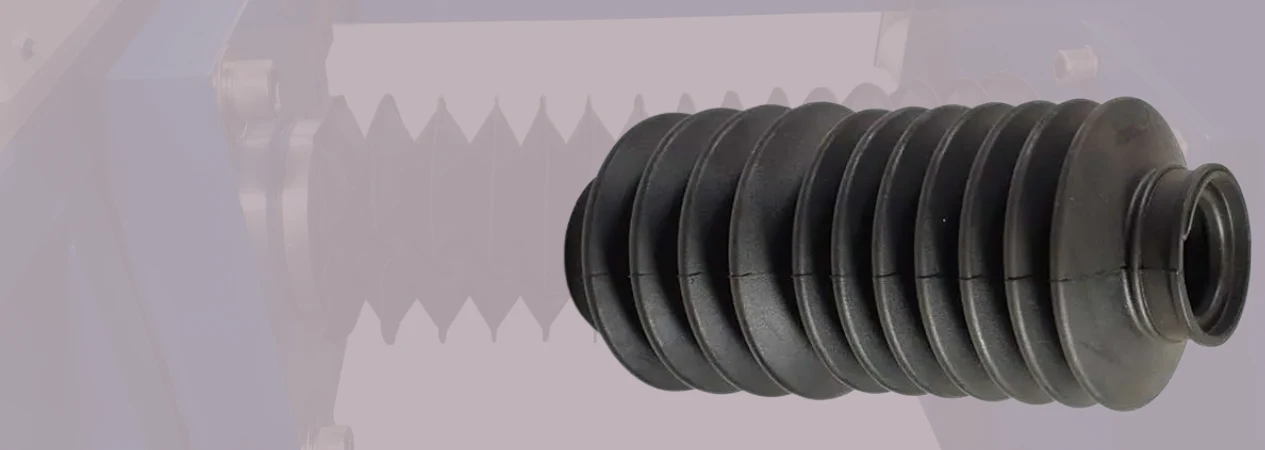

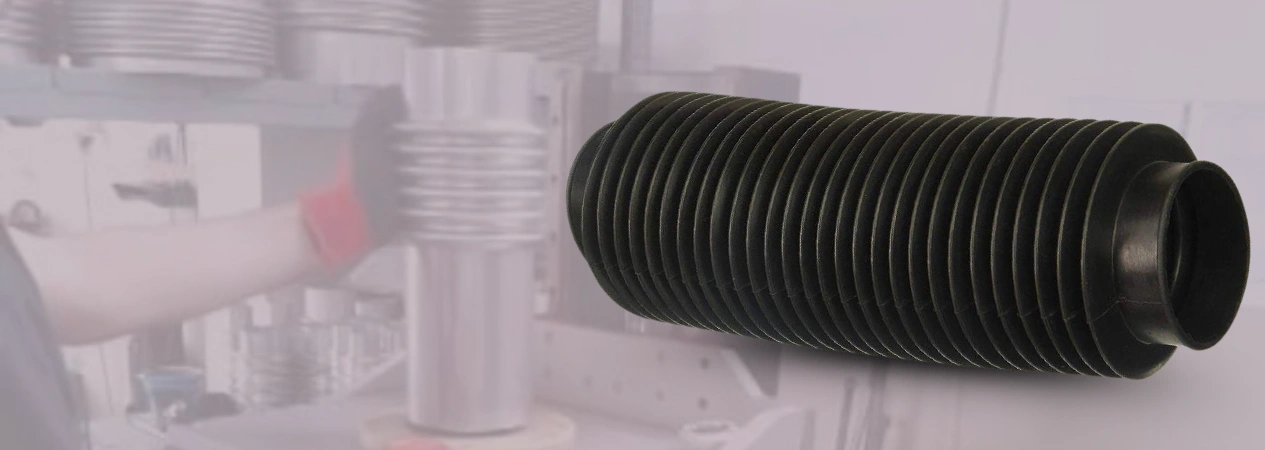

Rubber bellow seal manufacturers in the USA apply specialized coatings to minimize

friction-related damage. These thin protective layers create a barrier between

moving components and the rubber surface. PTFE linings help prevent

chemical attacks before they can degrade the underlying rubber compound, extending

service life in aggressive chemical environments.

Exterior rubber hardening is often achieved through a chlorination process, which

strengthens the outer surface without affecting the internal structure. This

treatment produces a tough, abrasion- and cut-resistant skin. Bellows boot

manufacturers in the USA also use plasma treatment on bonding surfaces, allowing

adhesives to bond more effectively through microscopic surface activation.

Some products receive lubricant layers directly during the molding process to further

reduce friction and wear during operation.

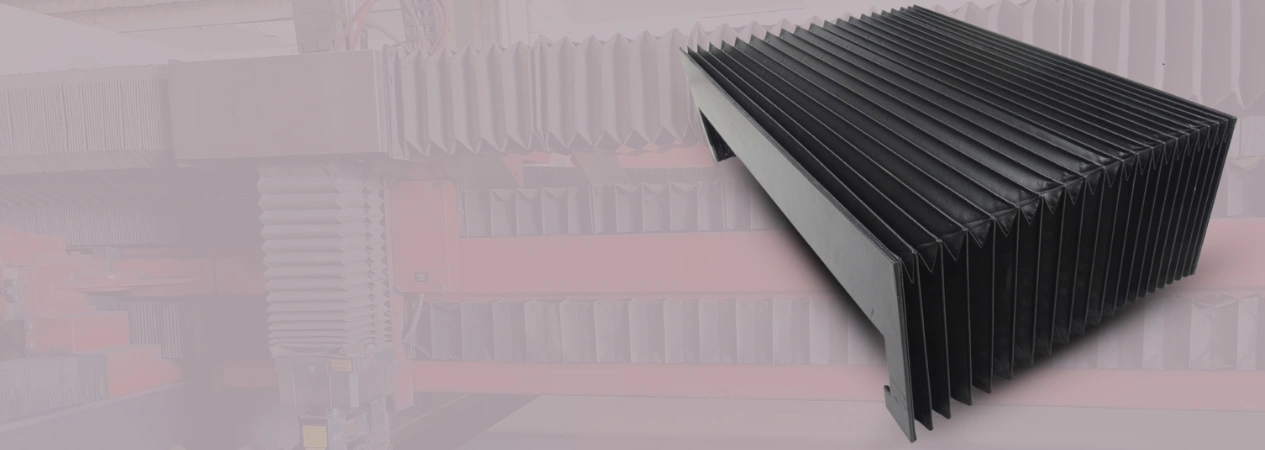

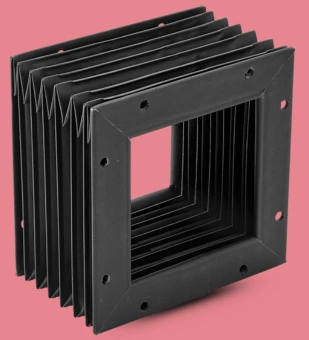

UV Filter Compounds

UV-resistant additives are blended into bellows designed for outdoor use to block

sun-related damage. These compounds help prevent cracking and color fading over years

of exposure. Surface texturing enhances both sealing performance and handling during

installation by increasing controlled friction.

- Anti-static treatments reduce dust buildup on critical surfaces.

- Hydrophobic coatings repel water from sensitive areas.

- Colour-fast treatments maintain appearance in harsh environments.

- Micro-texturing improves sealing without increasing wear rates.